Наши новости

Узнайте о наших последних новостях здесь.

Последние новости

- ▶ Почему стоит выбрать китайского поставщика змеевиков?

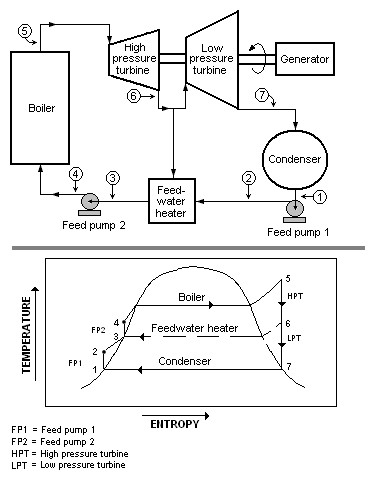

- ▶ Разница между высоконапорными и низконапорными подогревателями питательной воды на электростанциях

- ▶ Первая башня основного газового охладителя успешно установлена

- ▶ Разработано для первой системы охлаждения — башня первичного газового охладителя A на объекте JISCO

- ▶ Теплообменник из нержавеющей стали

- ▶ Теплообменник масляного котла: конструкция, принцип работы и промышленное применение

Сообщение

1. Обзор продукта

Змеевиковые трубы высокого давления перегревателя являются ключевыми компонентами под давлением в системах нагревательных поверхностей котлов. Обычно они размещаются в высокотемпературной конвективной зоне газохода котла и используются для дальнейшего нагрева насыщенного пара до требуемой температуры перегретого пара, обеспечивая стабильную подачу пара для паровых турбин или последующих технологических систем.

Конфигурация змеевиковых многоходовых труб эффективно увеличивает путь теплопередачи в ограниченном пространстве, повышая эффективность конвективного теплообмена со стороны газохода. Продукт широко применяется в энергетических котлах, промышленных котлах и системах парогенераторов с рекуперацией тепла (HRSG).

2. Конструктивные особенности

Змеевиковая многоходовая конструкция

Трубы расположены в регулярном змеевиковом порядке, обеспечивая длинные пути теплопередачи и высокую тепловую эффективность в условиях высокотемпературного газохода.Разработано для работы под высоким давлением

Конструкция соответствует требованиям эксплуатации котлов среднего, высокого и сверхвысокого давления, подходит для длительной работы при высоких температурах и давлениях.Стандартизированные соединения

Концы труб подготовлены в соответствии с требованиями соединения коллекторов и подходят для полнопроходной сварки встык, обеспечивая надежный монтаж и герметичность.Хорошая адаптивность к тепловым напряжениям

Змеевиковая конфигурация эффективно компенсирует тепловое расширение, снижая тепловые напряжения и повышая долговременную стабильность работы.

3. Материалы и производственный процесс

Типичные материалы

ASME / ASTM: SA-213 T22, T91, T12

Стандарты GB: 12Cr1MoVG, 15CrMoG и другие жаропрочные легированные стали

Производственный процесс

Холодная гибка или контролируемая горячая гибка

Строгий контроль радиуса гибки и овальности

Концы труб скошены по стандартам и защищены заглушками

Контроль качества

Полная прослеживаемость сырья

Размерный и визуальный контроль гнутых труб

Сертификаты испытаний материалов (MTC) предоставляются по требованию проекта

4. Типичные области применения

Перегреватели высокого давления в энергетических котлах

Конвективные нагревательные поверхности в промышленных котлах

Паровые системы в агрегатах HRSG

Высокотемпературные паровые системы на коксохимических, химических и энергетических установках

5. Преимущества продукта

Подходит для непрерывной работы при высоких температурах и давлениях

Компактная конструкция с высокой эффективностью теплопередачи

Высокая точность изготовления и хорошая согласованность монтажа

Возможность индивидуального проектирования и изготовления в зависимости от условий эксплуатации проекта

6. Позиционирование продукта

Змеевиковые трубы перегревателя высокого давления классифицируются как элементы котлов под давлением. Они разработаны и изготовлены для соответствия строгим требованиям безопасности, надежности и долговременной работы в котловых системах и принципиально отличаются от обычных теплообменных змеевиков или стандартных гнутых труб.

ПРОФЕССИОНАЛЬНАЯ КОНСУЛЬТАЦИЯ

Если вас заинтересовала наша продукция и вы хотите узнать более подробную информацию, оставьте сообщение здесь, и мы ответим вам как можно скорее.